Electrical Switchgear Testing, Maintenance & Cleaning

Switchgear Enclosures & Bus Bars Require Periodic Testing & Maintenance That Should Be Performed Yearly.

PowerCom performs numerous switchgear testing and maintenance procedures. We also work very closely with switchgear manufacturers to provide our customers with custom fit electrical equipment. PowerCom services electrical equipment from all manufacturers including; Siemens, General Electric (G.E.), Allen-Bradley, ABB, Square D/Schneider Electric, Eaton/Cutler-Hammer, Westinghouse, ITE, and more.

TYPES OF ELECTRICAL EQUIPMENT POWERCOM SERVICES

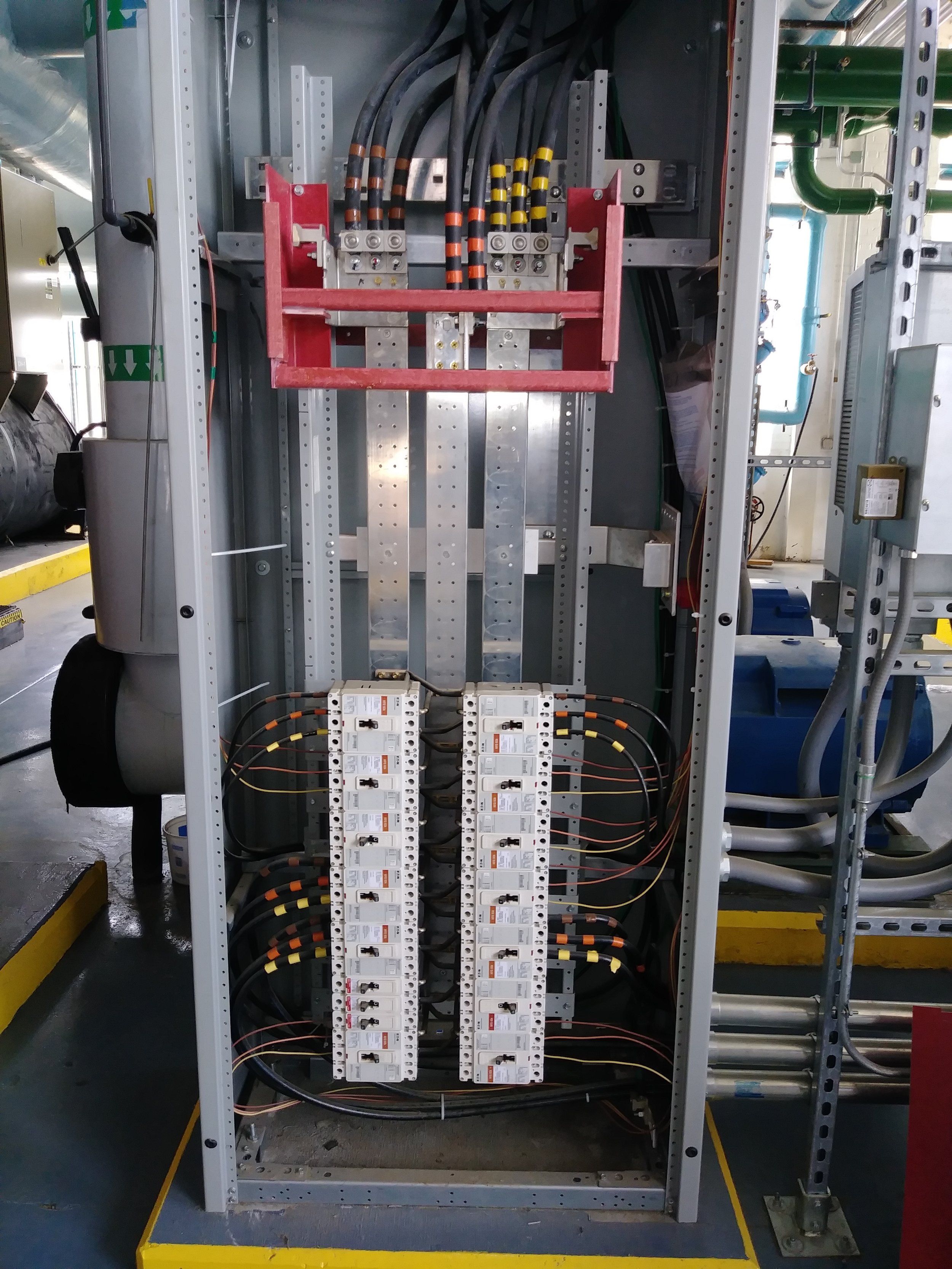

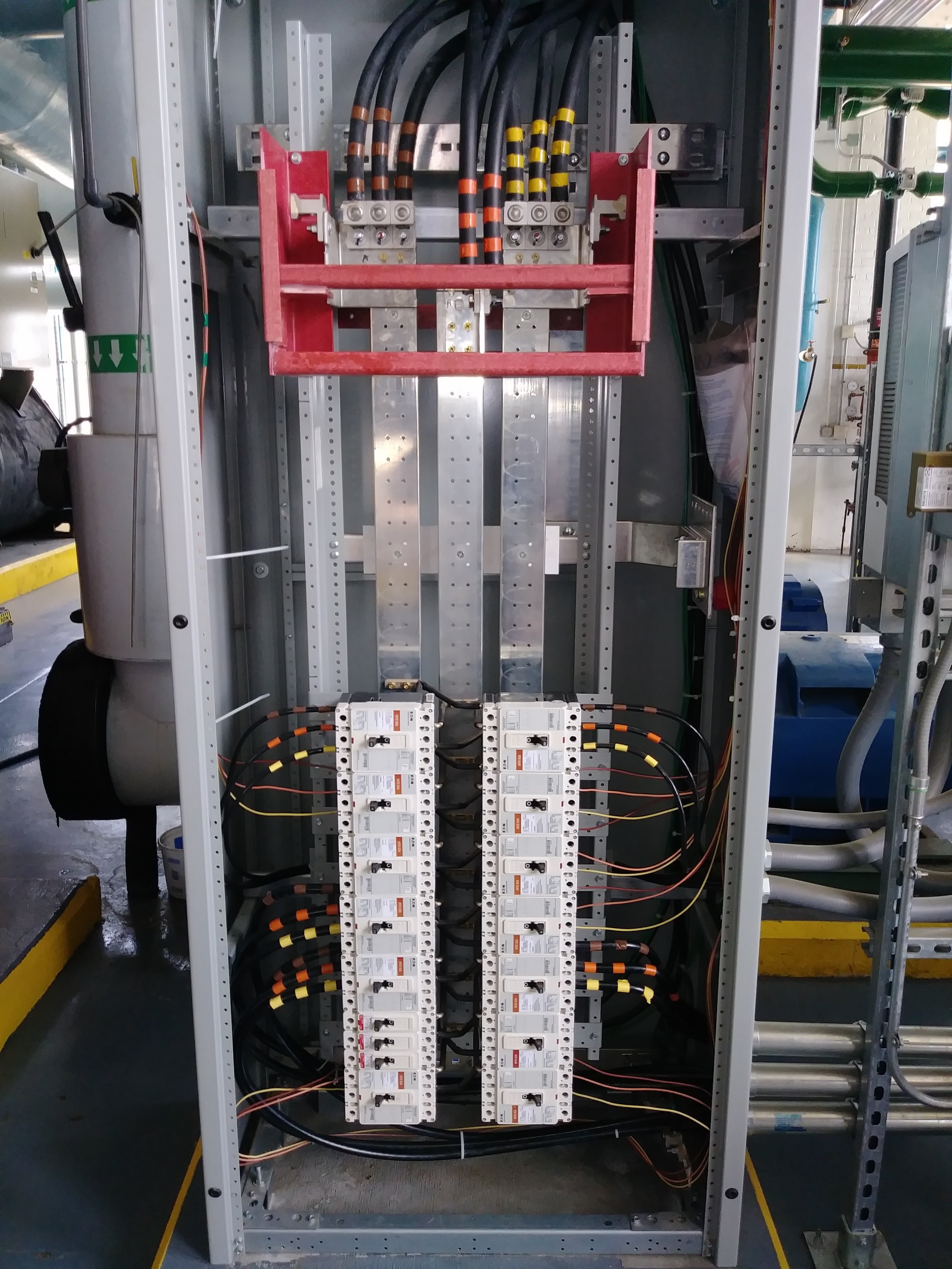

Switchgear – Indoor & Outdoor

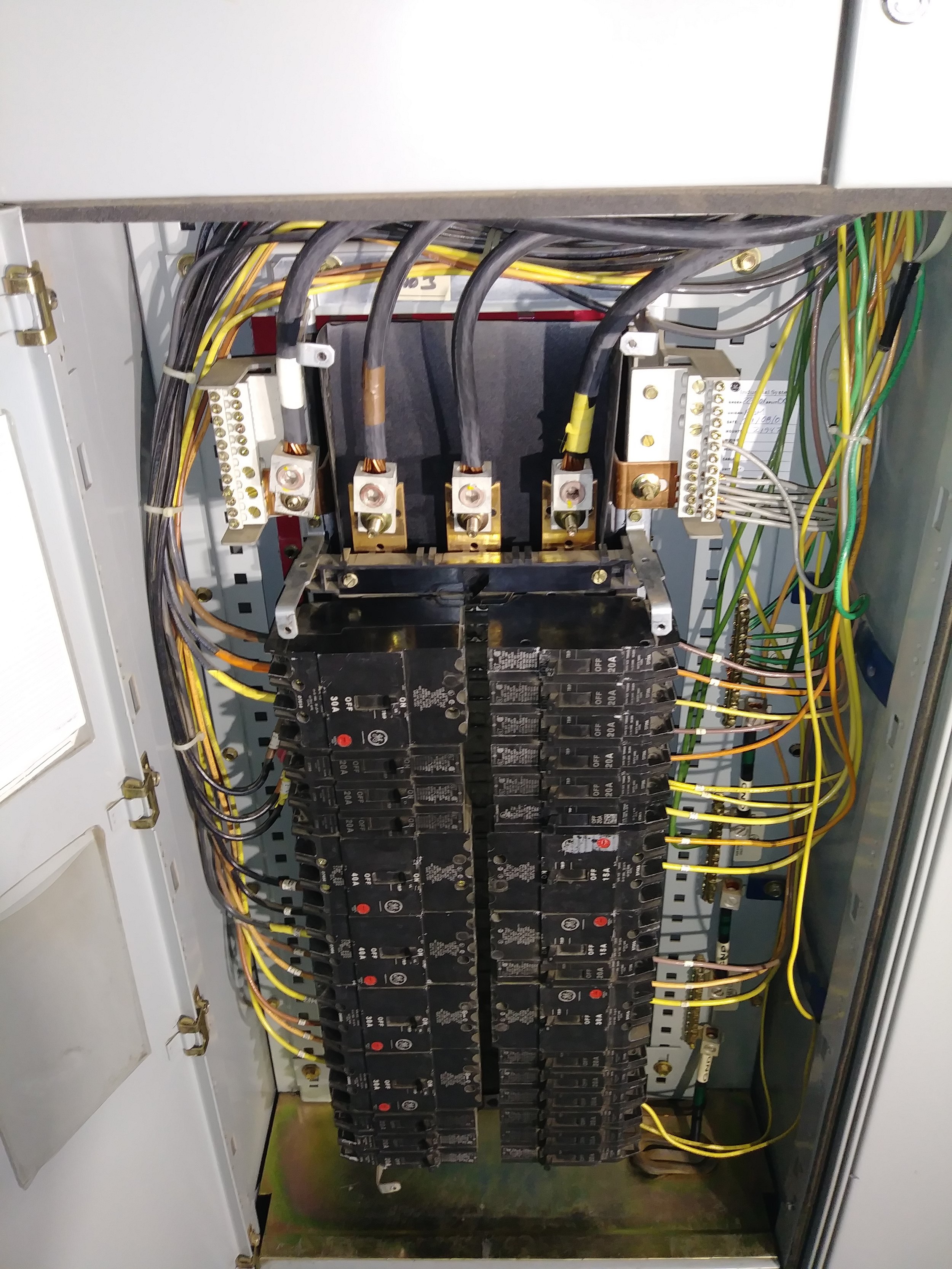

Panels & Panel Boards - All Voltages

Motor Control Centers - MCCs

Automatic Transfer Switches - ATS

Disconnect Switches

Fused Switches

Control Cabinets

Overhead Bus Systems

& More

The following are just some of the services PowerCom can provide for your switchgear and other electrical equipment.

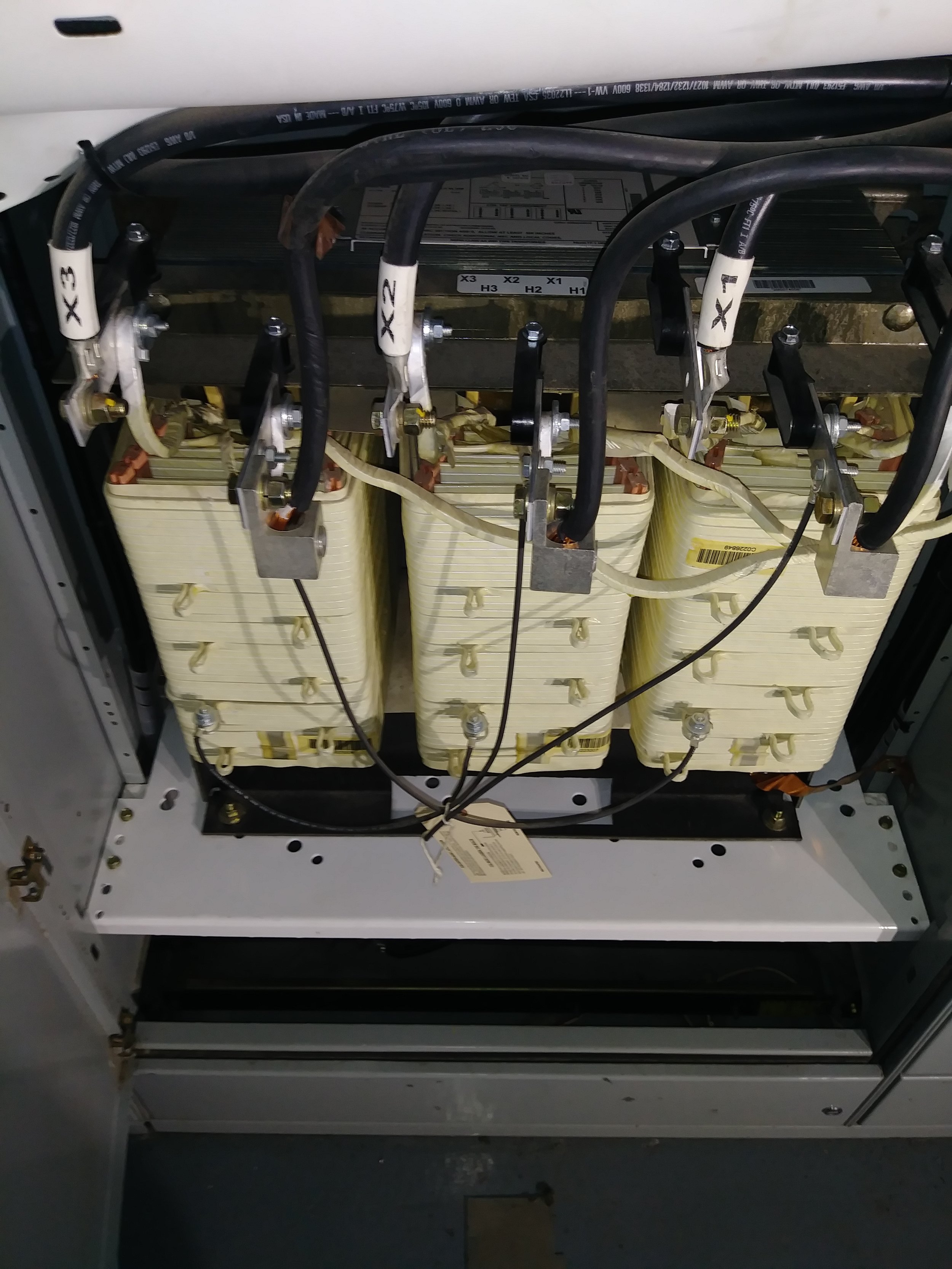

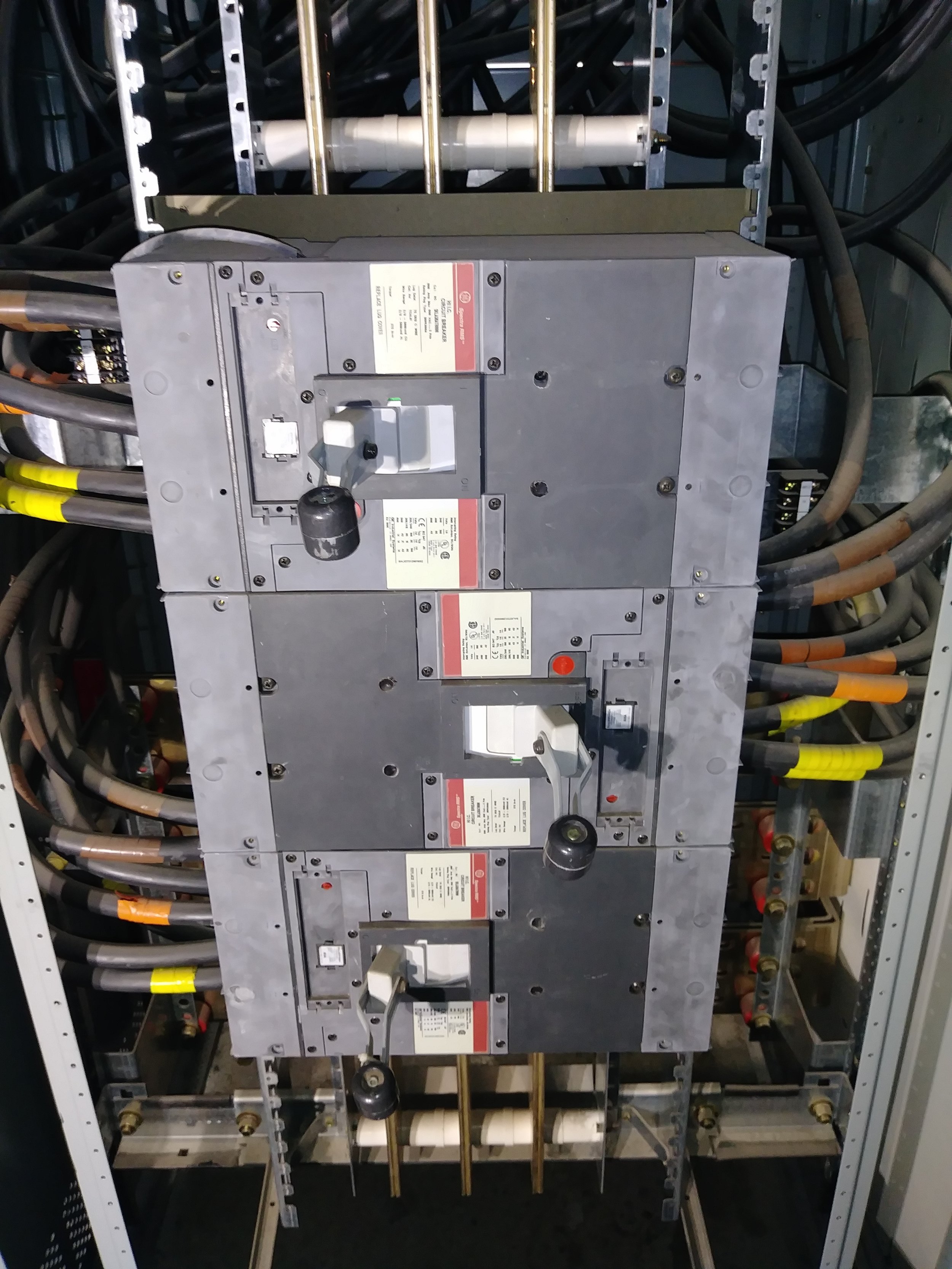

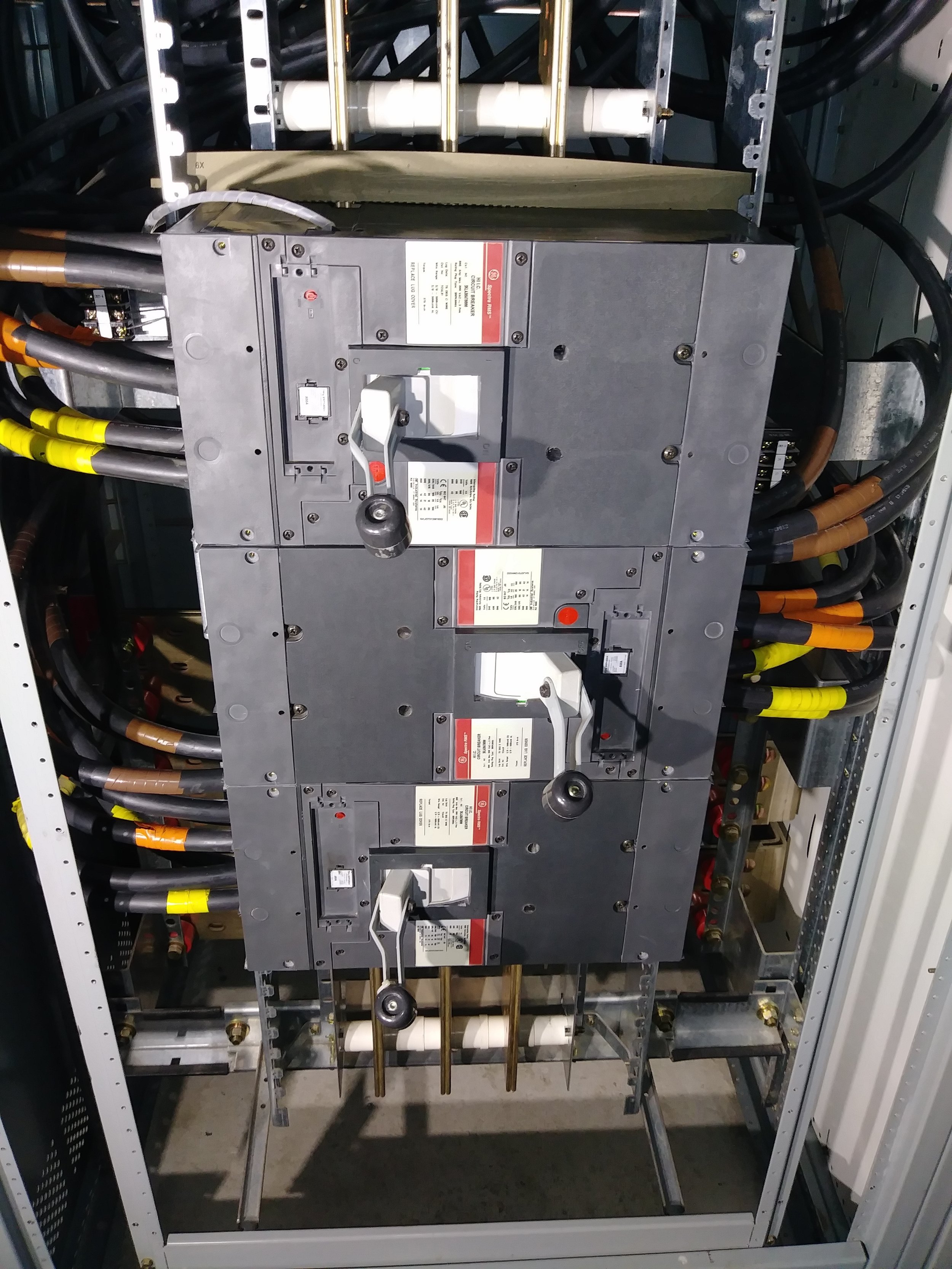

VISUAL AND MECHANICAL INSPECTIONS

A visual inspection of all insulating members will be performed for signs of electrical distress, tracking, corona, and thermal heating.

The enclosure will be thoroughly cleaned. All bus bar connections and splices will be inspected for signs of heating and then torqued. Various insulation tests will be performed and compared to previous tests for signs of weakening of the insulation system.

During the visual inspection, we carefully evaluate fused disconnect switches for any indication of excessive heating and metal discoloration. This is a sign of either poor contact alignment or loose hardware. Corrections would then be performed to the operating mechanism, whether electrical or mechanical. The equipment will be cleaned, lubricated and adjusted per manufacturer’s specifications.

INSULATION RESISTANCE TESTING - MEGGER TESTING

The insulation resistance test is a DC evaluation test of the insulation and gives a reliable indication of the presence of moisture, contamination or breakdown in the insulation. This test also establishes a benchmark for future comparative tests.

CONTACT RESISTANCE TESTING

If contacts are not maintained on a regular basis, resistance builds up due to repeated arcing, which in turn reduces the contacts’ ability to carry current. This test indicates the quality of mating of the contact surfaces and pivot points.

Contact resistance should be maintained as low as possible to reduce localized heating and power losses.